Acrylic has become an increasingly popular material for a variety of projects. Acrylic known for its flexibility and versatility; enables it to be used for many different projects. It’s surface is as hard as copper or brass. It is also versatile, in that it can be painted, glued, screen printed, routed, drilled, or sawed. You’ve probably encountered acrylic in your everyday life. Skylights, aquariums, dentures, and bone cement are all made of acrylic. Our Custom plastic products play to all the benefits of acrylic, while creating a product specific to our customer’s needs.

Acrylic Specifications:

PMMA Material: 100% virgin Lucite imported

Thickness: 20mm-1000mm

Color: Transparent

Density:1.2g/cm3

Transparency: 93%

Shape: customized shape

Packing: PE film masking on both sides, multi-layer KT board and iron structure packing

Advantages:

1. We can satisfy any requirement for customers

2. It is clear with high diaphaneity and translucency

3. It is easy to maintain clean with soap and soft cloth

4. Good insulation for all electrical equipment

5. It can bear large water pressure

6. Non-toxic to human

7. Light weight, only half weighted compared to the ordinary glass

8. Strong plasticity it can be easily shaped and processed

Acrylic Parameters:

No. | Item | Test Method | Result |

1 | Charpy Notched Impact Strength | GB/T 7134-2008 Section 6.5.3 & GB/T 1043.1-2008 | 19 kJ/m2 C (complete break) |

2 | Density | GB/T 7134-2008 Section 6.9.1 & GB/T 1033.1-2008 Method A | 1.184 g/cm3 |

3 | Flexural Strength | GB/T 7134-2008 Section 6.5.1 & GB/T 9341-2008 | 112MPa |

4 | Rockwell Hardness | GB/T 7134-2008 Section 6.5.4 & GB/T 3398.2-2008 | 114HRL |

5 | Tensile Modulus | GB/T 7134-2008 Section 6.5.2 & GB/T 1040.1-2018 & GB/T 1040.2-2006 | 3150 MPa |

6 | Tensile Strength | GB/T 7134-2008 Section 6.5.2 & GB/T 1040.1-2018 & GB/T 1040.2-2006 | 76.4 MPa |

Elongation at Break | 5.8% | ||

7 | Total Luminous Transmittance | GB/T 7134-2008 Section 6.8.1 & GB/T 2410-2008 Method A | 93.2% |

8 | The Size Change Rate After Heating(Shrinkage) | GB/T 7134-2008 Section 6.6.3 | Length -1.6% |

Width -1.8% | |||

9 | Vicat Softening Temperature | GB/T 7134-2008 Section 6.6.1 & GB/T 1633-2000 Method B50 | 112 ℃ |

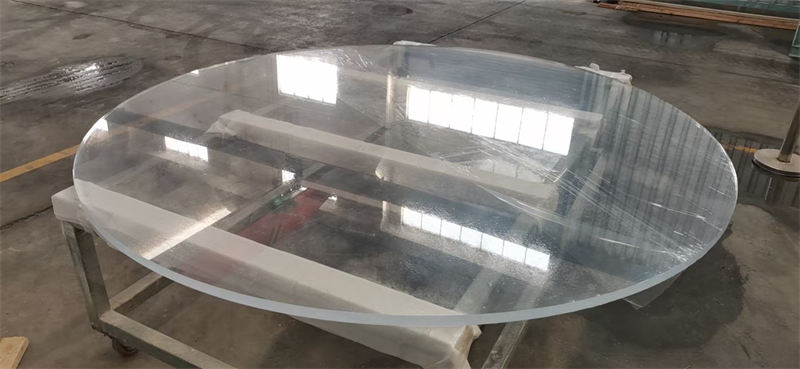

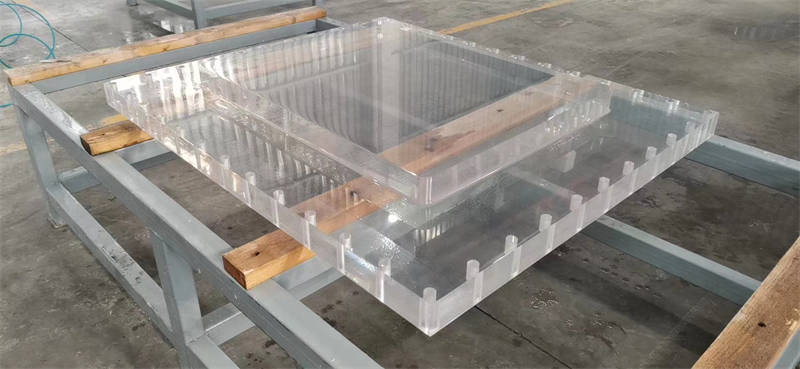

Pictures of Acrylic Panels:

Your email address will not published. Required fieled are marked.